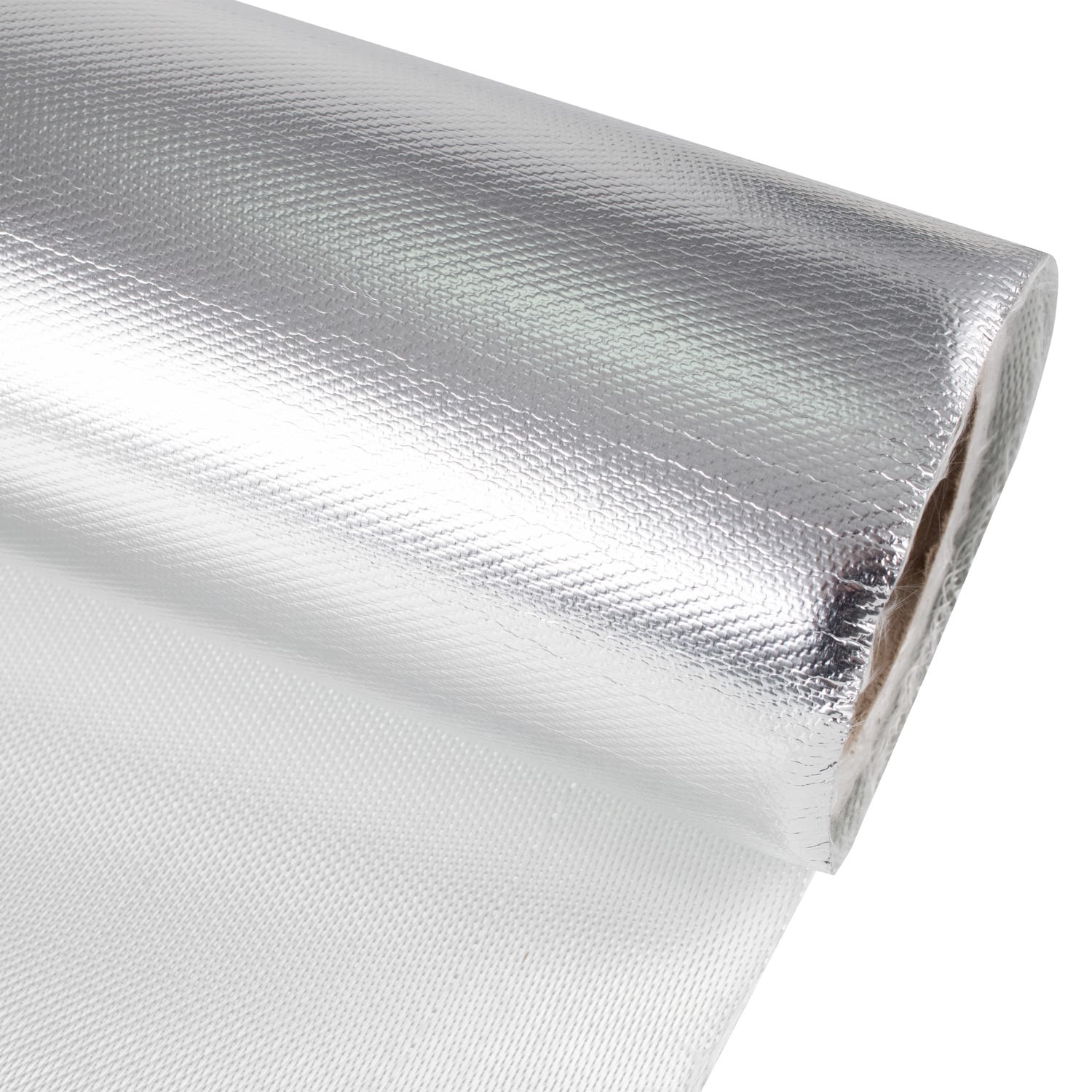

Aluminum foil fabric is not a single material, but is composed of two core parts: the "functional layer (aluminum foil)" and the "support layer (base fabric)". Some high-end products also add a "protective coating" to enhance specific performance.

Aluminum foil layer: Made of high-purity aluminum with a purity of over 99.5%, ultra-thin aluminum foil with a thickness of 0.01-0.05mm is produced through rolling process. This layer is the carrier of the core function of aluminum foil fabric, mainly responsible for reflecting thermal radiation, blocking water vapor and electromagnetic waves, while possessing excellent metallic luster and conductivity.

Base fabric layer: Depending on the application scenario, the base fabric material can be divided into fiberglass cloth, polyester cloth, nylon cloth, aramid cloth, etc. For example, glass fiber base fabric has strong temperature resistance and is suitable for high temperature environments; Polyester base fabric has good flexibility and is more suitable for folding or repeatedly bending scenes. The function of base fabric is to enhance the tensile strength and tear resistance of aluminum foil fabric, avoid the problem of aluminum foil being easily broken due to brittleness, and determine the overall weight and feel of the product.

Composite technology: The mainstream technology is divided into "hot pressing composite" and "glue composite". Hot pressing composite tightly adheres aluminum foil and base fabric through high temperature and high pressure, without chemical glue residue, making it more environmentally friendly; Adhesive bonding is achieved through high-temperature resistant adhesives, which are suitable for scenarios that require extremely high composite strength. Both processes ensure that aluminum foil and base fabric are not easily delaminated.

The core competitiveness of aluminum foil fabric lies in its versatility, covering multiple dimensions such as protection, insulation, and environmental protection, as follows:

1. Super strong barrier: isolates water vapor, corrosion, and electromagnetic waves

Water vapor barrier: The dense structure of aluminum foil can effectively block the penetration of water vapor, with a water vapor transmission rate (WVTR) of less than 0.1g/(m ² · 24h). It can be used for pipeline insulation layers and outdoor tent linings to prevent moisture and mold inside.

Chemical protection: Aluminum foil has good resistance to corrosive substances such as acid, alkali, and salt. When combined with chemical resistant base cloth, it can be used as equipment protective covers in chemical workshops and packaging materials for corrosive liquid transportation to prevent equipment or goods from being corroded.

Electromagnetic shielding: The conductivity of aluminum metal enables it to have electromagnetic shielding function, with a shielding effectiveness (SE) of 30-50dB, which can effectively block electromagnetic wave interference. It is suitable for electronic equipment casings and signal shielding covers of communication base stations to protect the stable operation of equipment.

2. Efficient insulation: Reflecting thermal radiation and reducing energy consumption

The insulation performance of aluminum foil cloth mainly relies on the principle of "thermal reflection" - the aluminum foil layer can reflect more than 90% of infrared thermal radiation, rather than the "passive insulation" of traditional insulation materials. This characteristic makes it stand out in two scenarios:

Low temperature insulation: used for the inner walls of refrigerators and cold chain transport carriages, reflecting the internal cooling energy and dissipating it outward, reducing the energy consumption of refrigeration equipment and extending the insulation time.

High temperature protection: used for outer protection of industrial kilns and boilers, reflecting high-temperature radiation inside the furnace, avoiding heat leakage and scalding personnel, while reducing the impact of environmental temperature rise on other equipment.

3. Physical durability: tensile, temperature resistant, easy to process

Tensile and tear resistance: The base fabric layer endows the product with excellent mechanical properties. The tensile strength of conventional polyester aluminum foil fabric can reach 200N/5cm, and the tear resistance strength is ≥ 50N. It can withstand certain stretching and impact, and is not easily damaged.

Wide temperature range adaptation: Depending on the material of the base fabric, the temperature resistance range can cover -60 ℃ to 500 ℃ (such as glass fiber base fabric, aluminum foil fabric with a temperature resistance of up to 500 ℃, and polyester base fabric with a temperature resistance of about 120 ℃), suitable for extreme high and low temperature environments.

Easy to cut and process: Products are usually supplied in roll form, with thin thickness (0.1-0.5mm) and light weight (50-200g/m ²). They can be cut into any shape according to needs, making it convenient to fit with other components such as pipeline wrapping and equipment shaped protection.

4. Environmental safety: non-toxic and recyclable

Non toxic and odorless: using food grade or industrial grade environmentally friendly raw materials, without the release of harmful substances such as formaldehyde and heavy metals, it can be used in food packaging (such as the outer layer of aluminum foil lunch boxes), children's toy protection and other scenarios.

Recyclable: Aluminum foil and base fabric can be recycled through a separation process, with a recovery rate of over 95% for aluminum foil, meeting the needs of environmental protection and circular economy, and reducing resource waste.